Search in blog

Blog tags

Photo gallery

No featured images

In industrial environments, where there is contact with water, oil, chemicals or moisture, standard encoders often fail. In such conditions, draw-wire encoders with IP68 tightness class, designed for operation in full submersion, are ideal. They provide reliable readings of position, angle or speed even in extreme conditions.

In the dynamically developing world of industrial automation, precision, reliability and durability of components are crucial. One of the most important elements in measuring systems are rotary encoders. In the Morkom-Tech.com store we offer a wide selection of encoders of the renowned Turkish company ATEK, which has been providing high-class solutions for measuring angular and speed speed for years.

In a dynamic industrial environment, precise monitoring of the position of machine elements is the basis of efficiency and safety. **FIAMA position indicators** are solutions that combine Italian engineering with the highest quality of workmanship. At Morkom-Tech, we deliver these devices to Polish companies – learn about their advantages and find out why it is worth choosing FIAMA!

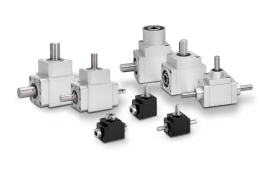

In an industry where every detail matters, **bevel gears** play a key role in power transmission and precise control of mechanisms. **FIAMA**, an Italian expert in mechanical components, has been providing solutions that set quality standards for decades. At Morkom-Tech.com we offer FIAMA bevel gears – check why it is worth investing in them!

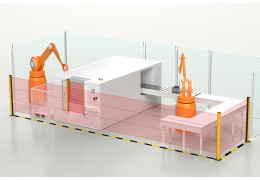

Optoelectronic safety curtains are one of the most modern solutions used in industrial automation, aimed at protecting employees and machines. Their operation is based on the emission and reception of light beams, which create an invisible barrier - any break in this barrier leads to the immediate stopping of the machine. In order to optimize their operation and reduce installation costs, light-reflecting mirrors are increasingly used, which allow for more efficient use of this system.

Learn about absolute magnetic encoders - their application, classification and advantages. Find out why they are irreplaceable in industry and how to choose the right model. Check out the offer in our store!

Draw-wire encoders are devices that play a key role in industrial automation, enabling precise measurements of length, position or speed. When an inclinometer is additionally integrated in a draw-wire encoder, the measurement capabilities of the device are significantly expanded, making it an even more versatile tool in modern industrial applications

Safety optoelectronic curtains are a key element of industrial safety systems. They provide protection for people and machines in production processes. In order for their installation to comply with applicable regulations, appropriate safety standards must be met and the required certificates must be obtained. In this article, we will discuss what standards must be met when installing optoelectronic curtains and why certification is necessary.

Ultrasonic sensors are devices used to measure distances, detect objects or monitor the level of liquids and bulk materials. They operate on the principle of emitting sound waves with frequencies higher than those audible to the human ear (usually above 20 kHz) and analyzing their reflection from encountered obstacles. In this article, we will present a detailed classification of ultrasonic sensors, discuss their types of outputs and show the most popular applications.

Lidar (Light Detection and Ranging) is a technology that uses laser light to precisely measure distances. Lidar laser scanners are used in many industries – from automotive to geodesy – and their ability to create three-dimensional maps of the surface of the terrain or objects makes them uniquely applicable in modern engineering and technological applications.

Rotary encoders are devices used to measure the angle of rotation, rotational speed and position in machines and automation systems. They enable precise monitoring of movement in industrial applications, robotics, and everyday devices. In this article, we will discuss the most popular types of rotary encoders: magnetic and optical, and their applications.

Pressure transducers are measuring devices that convert pressure into an electrical signal. In practice, they are used to precisely monitor and control the pressure level in various industrial and technological processes. These transducers are widely used in many industries, such as the chemical, food, pharmaceutical and oil industries, where pressure control is crucial for the proper operation of machines and processes.